Enhancing Your Finishing Process with Anodizing Equipment

In the world of finishing systems, anodizing equipment plays a crucial role in achieving durable, corrosion-resistant, and aesthetically pleasing surface finishes. Anodizing is a process that enhances the properties of metal surfaces by creating a protective oxide layer through electrolytic passivation. This process not only improves the appearance of the metal but also increases its durability, insulation, high reflectivity, and resistance to wear and corrosion.

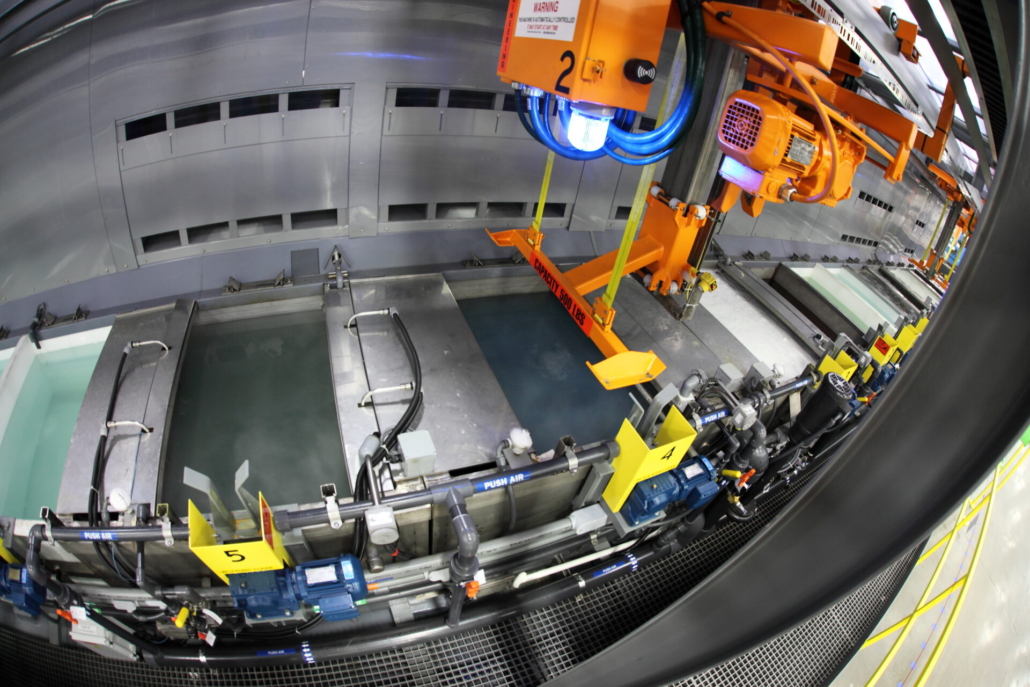

Every system, regardless of its size, is individually tailored to suit the unique demands of the intended application. The process of determining the ideal size and configuration of an anodizing line entails a comprehensive evaluation that takes into account various factors, including electrical capacity, desired final finish and color, production requirements, tank dimensions, and waste management. These considerations not only impact the total cost of the system but also guarantee its efficiency and effectiveness.

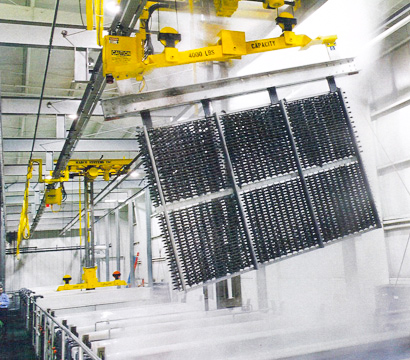

One of the key benefits of using anodizing equipment is the precision and consistency it offers in the anodizing process. By leveraging advanced technology and automation, KOCH Finishing Systems’ equipment ensures uniform and high-quality anodized finishes, resulting in enhanced product performance, durability, and aesthetics. You can achieve vibrant colors and a sleek finish that enhances your products.

Another standout feature of anodizing equipment is its versatility and customization options. Whether you need a small-scale anodizing solution for batch processing or a large-scale automated system for high-volume production, the equipment can be designed to suit your specific requirements. Additionally, anodizing is most commonly used for coating aluminum but, it can also be used as a process on titanium, or cadmium substrates.

Furthermore, KOCH’s commitment to sustainability and environmental responsibility is evident in the design and implementation of our anodizing systems. The Koch engineering team is committed to designing equipment that will minimize waste, energy consumption, and environmental impact. This allows you to achieve superior anodized finishes while reducing your carbon footprint and operating costs.

In conclusion, investing in anodizing equipment is a strategic decision that can elevate your finishing process, improve product quality, and drive overall efficiency. With a focus on innovation, quality, and sustainability, anodizing equipment is a reliable and cost-effective solution for businesses looking to enhance their surface finishing capabilities.

About KOCH Finishing Systems

When it comes to anodizing equipment, KOCH Finishing Systems stands out as a leading provider of innovative solutions that elevate the finishing process to new heights. We pride ourselves on providing high-quality anodizing system solutions that meet the most stringent industry standards. With a focus on automation, efficiency, and quality, KOCH’s anodizing equipment is designed to meet the diverse needs of industries such as automotive, aerospace, electronics, and more. Our team of experts will work closely with you to gather the necessary information and specifications to design a system that meets your requirements.

To learn more about KOCH’s anodizing equipment and how it can benefit your business, visit our anodizing equipment page. Elevate your finishing process with KOCH Finishing Systems today!