Top 7 Preventative Maintenance Measures for Paint, Plating, and Anodizing Lines

Downtime in a finishing line doesn’t always come from a blown motor or a failed burner. Sometimes, it starts quietly — with a mistuned sensor, a corroded anode, a clogged filter, or a misaligned spray nozzle. Small issues that lead to rework, defects, and missed ship dates if they go unchecked.

Preventative maintenance is what keeps that from happening. This article covers seven essential measures every facility should be building into its maintenance program. Some are technical. Some are procedural. All of them are practical and field-tested across real-world paint, plating, and anodizing systems.

1. Conduct Regular Finishing System Audits

Routine audits bring clarity. They uncover issues that don’t trigger alarms but still drag down performance. A thorough system audit should include:

- Performance checks: Confirm pumps hold pressure and sensors give accurate readings.

- Component wear: Watch for chain stretch, eroded tips, or burners running out of range.

- System interaction: Ensure equipment is working in sync, not just functioning individually.

- Compliance and safety: Review ventilation, interlocks, signage, and access points.

Annual audits create benchmarks. Audits after upgrades or layout changes help recalibrate. Routine audits identify issues before they turn into emergencies.

2. Inspect and Maintain Applicators, Anodes, and Dispensers

Applicators wear down. Anodes degrade. Dispensers clog. These components directly affect coating and plating quality.

Watch for:

- Widened spray tips that alter pattern and volume

- Inconsistent current caused by degraded anodes or weak contacts

- Clogged valves that disrupt chemical delivery

- Cross-contamination in shared lines

Regular inspections help catch these issues early. Test spray patterns. Check current distribution. Compare identical units to spot deviations. Clean with non-abrasive tools and replace worn parts before they impact quality.

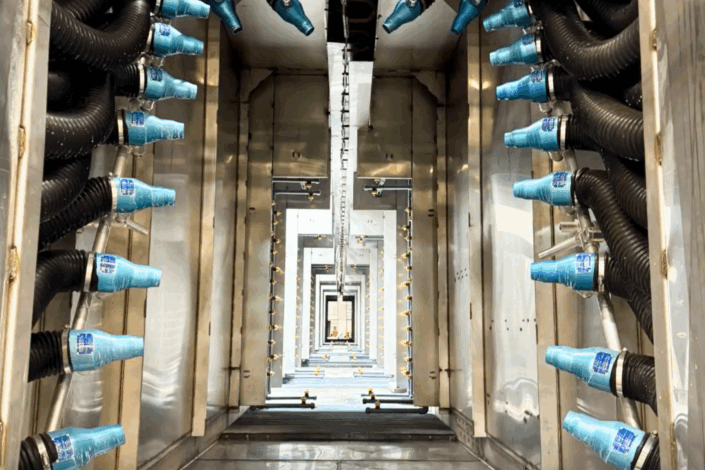

3. Monitor And Maintain Proper Airflow And Filtration

Airflow keeps overspray out of finishes and vapor levels within safe limits. When filters load up or ducts leak, everything from finish quality to worker safety is at risk.

Best practices include:

- Monitoring static pressure across intake and exhaust filters

- Replacing filters based on actual use, not the calendar

- Inspecting for bypasses near seams and gaskets

- Checking ducts for corrosion, leaks, or loose fittings

Poor airflow can lead to compliance issues with OSHA, NFPA, and EPA standards. Stay ahead by tracking airflow metrics and replacing filters before problems show up on the shop floor.

4. Conduct Regular Conveyor and Material Handling Inspections

Reliable part movement is critical. A dragging trolley or a misaligned lift throws off dwell times and finish consistency.

Observe your system running both empty and loaded. Look for:

- Chain stretch or poor lift timing

- Misaligned or worn carrier arms

- Damaged racks or contact points

- Build-up on rails

- Gaps in lubrication or use of incorrect grease

A part that doesn’t move predictably won’t finish properly. Maintain the mechanics that drive the process.

5. Maintain Proper Temperature, Current, and Chemistry Controls

Minor variations in temperature, voltage, or chemical concentration can ruin a finish. Calibration ensures consistency.

Key checks include:

- Coating systems: Verify oven sensors and airflow. Map temperatures using thermocouples, not just displays.

- Plating and anodizing: Confirm rectifier output, electrode ratios, and tank temperature.

- Chemistry: Track pH, concentration, conductivity, and temperature with control charts.

Many assume chemistry is the culprit when finishes fail. Often, the issue is temperature control or equipment drift. Map it, test it, and trust data over assumptions.

6. Proactively Replace Worn Components

Failures rarely happen without warning. Belts, seals, bearings, and nozzles all give subtle signs before failing.

To stay ahead:

- Track usage cycles and replace high-wear parts before failure

- Keep inventory of common wear items like seals, hoses, spray tips, and door gaskets

- Document change-outs to understand lifespan trends

You don’t need a complex software system. A simple log and a proactive mindset can prevent most unplanned downtime.

7. Train Maintenance Teams On Best Practices

Training should grow with your equipment, team, and throughput. Don’t treat it as a one-time event.

Include:

- Early failure detection across mechanical, electrical, and chemical systems

- Proper cleaning and reassembly of applicators

- Calibration techniques for ovens, pumps, and sensors

- Safety and compliance responsibilities

Refresh training every six months, especially after process changes. A well-trained team prevents issues, not just fixes them.

Maximizing Uptime And Efficiency Through Preventative Maintenance

Every one of these measures leads back to visibility. You can’t fix what you can’t see. Routine audits, tracked metrics, and well-trained teams all help you catch problems early, adjust before failure, and extend the life of your system.

Koch Finishing Systems can help you build that visibility. Contact us today to schedule your system audit.