KOCH Finishing Systems’ curtain coating systems provide precise control of liquid coating applications onto flat substrates of all types and are available in widths ranging from 12”-144”. Curtain coaters are used to apply solvent, waterborne, adhesive, and UV coatings at elevated temperatures. Curtain coaters can also be used to apply wax to corrugated box materials.

Benefits

Cost Efficiency: Curtain Coaters yield minimal production costs and decrease footprint by recycling unused coating material in a reservoir tank.

High Production Rates: Curtain coating shortens lead time by allowing users to accelerate the speed of the falling curtain between 200 – 1,000 feet per minute.

Uniform Film Build: Curtain coaters can achieve a desired coat weight with an adjustable pump and conveyor.

Versatility: Typical applications for curtain coating include:

- Furniture

- Doors and windows

- Moldings

- Electronics

- Metal decorating

- Adhesives

- Glass (screen printing) and plastics

Features

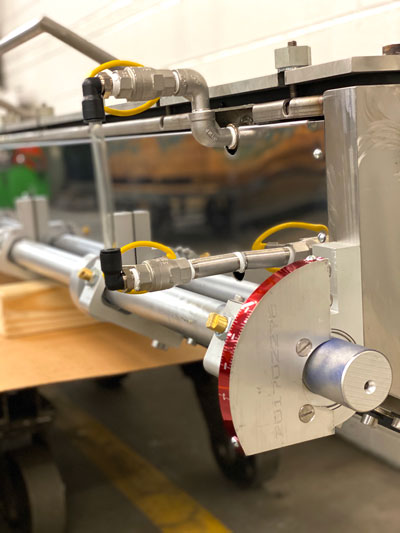

- Stainless steel pressure head to provide greater corrosion resistance than other applicators and simplify clean-up

- Top-open design head for easy access cleaning

- Adjustable head height for fine tuning of the unit to create a more consistent curtain

- Adjustable knife opening to provide fine tuning of curtain flow

- Knife opening indicator allows operator to set the desired opening

- Sight glass in pressure head to allow user to monitor liquid levels, this assists the operator in keeping an eye on material levels

- Variable speed pump drive and speed indication to allow for fine tuning of application spread and coat weight

- Digital speed conveyor drive and speed indication to allow for fine tuning of application spread and coat weight